Adjusting valve lash is a critical maintenance step that’s often overlooked, yet it’s key to keeping your engine running smoothly. I’ve found that a well-tuned valve train not only cuts down on unwanted noise but also ensures peak performance from your engine.

Whether you’re a seasoned mechanic or a weekend warrior under the hood, getting valve lash right can be a game-changer. I’ll guide you through the process, so you can dial in the perfect clearance and keep your engine purring like a kitten.

What is Valve Lash

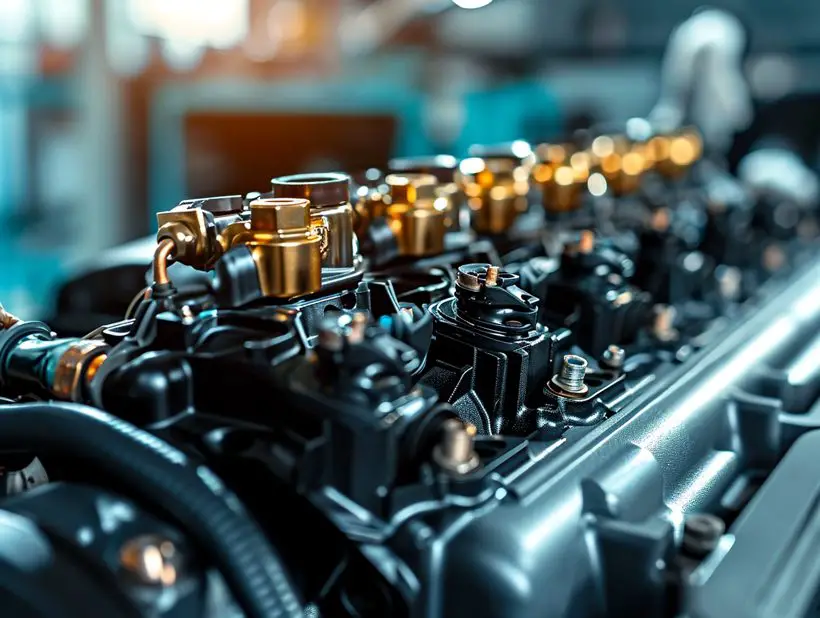

When I’m tinkering under the hood, I often get asked what exactly valve lash is. It’s a term that might throw you for a loop if you’re not familiar with engine mechanics. Simply put, valve lash is the term used to describe the small gap between the rocker arm and the valve stem tip. This gap is critical for several reasons:

- Ensures Proper Valve Closure: Without the right lash, valves may not close completely.

- Compensates for Thermal Expansion: Engines get hot, and parts expand. The lash allows for this expansion.

- Maintains Engine Timing and Operation: Proper lash ensures that the valve opens and closes at the right time.

Without this gap, as the engine heats and parts expand, you could end up with a valve that won’t close properly. This leads to a host of issues, the least of which is the annoying clatter that first draws attention.

How Valve Lash Impacts Engine Performance

To comprehend the effect of valve lash on engine health and performance, envision the role of valves. They serve as gatekeepers, allowing fuel and air in and exhaust out. They need to seal tightly for your engine to maintain compression. If lash is incorrectly set, the intricate dance between the camshaft lobes, lifters, and valves is thrown off. Here are the specific ways improper lash can hinder your car’s performance:

- Reduced Power: If valves open late or close early, your engine’s power output drops.

- Poor Fuel Economy: Precision in timing equates to efficient fuel use. The wrong valve lash can increase consumption.

- Increased Wear: Parts not moving as they’re designed to could lead to premature wear.

- Potential for Damage: Neglecting valve lash could lead to burnt valves or damaged pistons, culminating in costly repairs.

To underscore the point, keeping valve lash within the manufacturer’s recommended specifications is not just about minimizing noise‚Äîit’s about safeguarding the harmony of your engine’s operation and elongating its life. By accurately setting valve lash, you’re tuning the engine for peak performance and ensuring that each component works in concert. It’s an essential part of routine engine maintenance that too many overlook.

Why Adjusting Valve Lash is Important

When I’m under the hood, I often meet fellow car owners who underestimate the importance of valve lash adjustment. After explaining what valve lash is, it’s my job to clarify why this often overlooked maintenance step shouldn’t be ignored.

Adjusting valve lash is pivotal for several reasons:

- Optimal Engine Performance: A well-tuned valve lash ensures that engine components operate at their peak efficiency. The engine runs smoother, reacts to throttle changes more responsively, and overall, provides a more enjoyable driving experience.

- Longevity of Engine Parts: By maintaining the recommended clearance, the wear on valve components is minimized, consequently extending their service life. Precise lash adjustments prevent the valves from seating too hard or not seating fully, both of which can lead to early wear or damage.

- Preventing Noise: An engine with improperly adjusted valve lash often produces a ticking or clattering noise. This is not just unpleasant to the ear but is a telltale sign that something’s amiss. An accurate adjustment silences the clamor, giving you a quieter ride.

- Fuel Efficiency: Believe it or not, improper valve lash can hurt your fuel economy. An engine that’s working harder than it needs to will burn through fuel faster, costing you more at the pump.

I frequently point out that valve lash adjustment is also about preventing bigger issues down the road. If left unaddressed, incorrect valve lash can lead to:

- Incomplete valve closure, which impacts the engine’s ability to compress the air-fuel mixture effectively

- Excessive valve wear, potentially resulting in burnt valves

- Impaired engine timing, leading to a decrease in power and performance

Every vehicle has its own specification for valve lash, tailored to its unique needs. That’s why it’s crucial to follow the manufacturer’s recommendations for your particular model. Remember, regular checks and adjustments are key to ensuring that your engine functions as quietly and efficiently as possible.

Through faithful adherence to your vehicle’s maintenance schedule and precisely adjusting the valve lash as needed, you’re not just avoiding unnecessary noise; you’re also safeguarding your engine’s health and your wallet.

Tools Needed for Adjusting Valve Lash

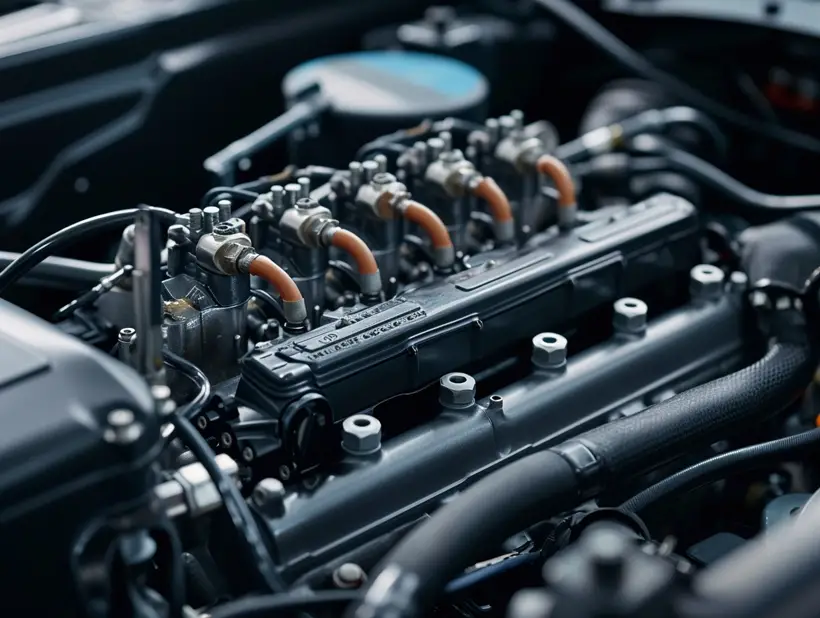

Before diving into the valve lash adjustment process, it’s essential to gather the right tools. Having everything on hand streamlines the task and helps prevent any unwanted interruptions. Here’s what I typically have in my toolbox for this job:

- Feeler gauge: This tool is crucial for measuring the gap between the rocker arm and valve stem. Precision is key, so a quality feeler gauge with a range of sizes is a must-have.

- Wrench set: Adjusting valve lash often requires loosening and tightening lock nuts. A set of wrenches, especially a torque wrench, ensures that you can apply the correct amount of force when needed.

- Screwdriver or hex key: Depending on the design of your engine, a flat-head screwdriver or a hex key will be necessary to turn the adjustment screw.

- Ratchet and socket set: For removing engine covers or any other components that may obstruct access to the valves, a reliable ratchet and socket set comes in handy.

- Workshop manual: A specific workshop manual for your car model provides invaluable information, including the precise valve lash measurements for your engine.

Make sure to lay out all your tools in an organized manner to help facilitate the process. Good lighting and clean work environment also play a pivotal role in ensuring accuracy while making adjustments.

Once you’ve got your tools sorted, you’ll want to ensure the engine is cold before you start. Metal expands when hot, which can lead to incorrect valve lash measurements. Patience is a virtue in this delicate procedure, so I always give my car ample time to cool down.

In the next section, I’ll guide you through the steps of actually adjusting the valve lash, so you can get back on the road without the grumble of engine noise under the hood.

Step-by-Step Guide to Adjusting Valve Lash

When it’s time to make the adjustments to a cold engine, I like to begin by locating the top dead center (TDC) on the compression stroke for cylinder number one. Once I’ve found TDC, it’s more straightforward to follow the firing order of the engine as listed in the workshop manual, ensuring every valve is adjusted in sequence.

Here’s how I approach the process:

- Identify TDC: Rotate the crankshaft with a ratchet and socket until the timing mark on the harmonic balancer aligns with the TDC mark on the timing cover.

- Adjust the First Valve: Using the correct size wrench and feeler gauge, I’ll loosen the lock nut on the valve adjuster and insert the feeler gauge between the rocker arm and valve stem.

- Tighten to Specification: While keeping the feeler gauge in place, I’ll tighten the adjuster until there’s a slight drag on the gauge, then torque the lock nut to the specification in the workshop manual.

- Check and Move On: After double-checking the adjustment, I move on to the next valve in the firing order, repeating the process.

It’s important to be meticulous during this process. The goal is to achieve a precise gap that promotes optimal engine performance and quiet operation. Adjusting valve lash isn’t about speed; it’s about precision.

Throughout the adjustment workflow, I keep a close eye on the following:

- All specifications from the workshop manual

- The order of cylinders to prevent any mix-ups

- The drag on the feeler gauge to ensure it’s not too loose or tight

By adhering to the sequence and being detail-oriented, I ensure that each valve is adjusted to support the engine’s smooth performance without unnecessary noise or wear. Each step is a move towards a quieter ride and reliable operation.

Common Mistakes to Avoid

As someone who’s passionate about automotive maintenance, I’ve seen my fair share of common errors that can occur when adjusting valve lash on an engine. It’s crucial to be aware of these potential pitfalls to prevent unnecessary engine noise and to maximize the engine’s performance. Here’s what you should keep an eye out for:

- Incorrectly Identifying TDC: One key step is ensuring you’ve properly found the top dead center for cylinder number one. Misidentifying TDC can lead to improper valve adjustments and a poorly performing engine.

- Overlooking the Engine’s Firing Order: Each engine has a specific firing order and if you adjust valves out of sequence, it can result in uneven performance.

- Inadequate Tightening or Over-tightening: It’s imperative to tighten the valves to the exact specifications provided by the manufacturer. Too loose and you’ll hear noise; too tight and you risk damaging the engine.

- Not Using the Right Tools: Always use the proper sized wrenches and feeler gauges. Using incorrect tools can lead to inaccurate adjustments.

- Rushing the Process: Valve adjustment requires patience. Rushing can result in mistakes. It’s vital to take your time with each adjustment to ensure accuracy.

Avoiding these mistakes comes down to being meticulous and following the correct procedures step-by-step. Remember:

- Read the manual for your specific engine beforehand.

- Prepare the necessary tools.

- Allow yourself plenty of time to ensure precision.

Over time, you’ll develop a rhythm that makes adjusting valve lash a more streamlined process, contributing to the longevity and reliability of your engine. There‚Äôs always more to learn and with each valve adjustment, your expertise grows, so do the performance and quiet operation of your vehicle.

Benefits of Properly Adjusted Valve Lash

When I’m under the hood, tweaking each valve to its precise clearance, I’m not just going through the motions. There’s methodical intent because properly adjusted valve lash is akin to a well-conducted orchestra; every component works in harmony, leading to a suite of benefits that are hard to ignore.

Firstly, let’s talk performance. A fine-tuned valve lash ensures that the valves open and close at the right moment, allowing for optimal air-fuel mixture intake and exhaust gas expulsion. This precise timing is critical in:

- Enhancing engine efficiency

- Boosting power output

- Improving fuel economy

These improvements aren’t just numbers on a dial; they translate to a more responsive throttle and a livelier ride. Next up is durability. It’s no secret that an engine is a culmination of numerous moving parts, and excessive valve lash can spell trouble for these components. Here‚Äôs what proper adjustments can prevent:

- Premature wear of valve components

- Unnecessary stress on the engine

- Potential for expensive repairs down the line

Consistent valve lash maintenance also contributes to smoother idling and quieter engine operation. We’ve all heard the tell-tale clatter of a valve-train begging for adjustment. Keeping lash within manufacturer specifications means a more serene driving experience ‚I not to mention less embarrassment at stop lights.

Maintaining the correct valve lash doesn’t just benefit your engine’s current state but safeguards its longevity. It’s like investing time in dental care; ignore it, and you’ll face a hefty bill eventually. But stick to a proactive approach, and you’ll reap ongoing reliability. Here’s a snapshot of the pros:

| Benefit | Description |

|---|---|

| Enhanced Performance | Precise timing leads to better engine efficiency. |

| Extended Component Lifespan | Reduces wear on valves and related components. |

| Quieter Engine Operation | Decreases the noise produced by the valvetrain. |

| Increased Fuel Economy | Optimal valve function can improve fuel consumption. |

Skilled valve lash adjustments are an art form in their own right ‚Äî a harmonious balance that can elevate the mundane task of engine maintenance into a rhythmic dance that benefits both machine and driver. And when I’ve finished my adjustments, I’ll listen for the sweet purr of an engine that’s running just as it should.

Conclusion

Perfecting valve lash adjustments is key to unlocking your engine’s full potential. My deep dive into this topic has shown that it’s not just about keeping noise at bay‚Äîit’s about delivering peak performance and ensuring your engine’s health. With every turn of the wrench, you’re investing in your vehicle’s future, preventing costly repairs, and reaping the benefits of a well-tuned machine. Remember, a quiet engine is a happy engine and a reflection of your attention to detail. So take pride in mastering this skill and enjoy the satisfaction that comes with a job well done.