Dealing with a mysterious gas smell can be both annoying and worrisome. I’ve been there, and I know it’s often a sign of an evaporative emission system (EVAP) leak. This system is crucial for reducing harmful emissions, and when there’s a leak, it’s not something to ignore.

I’ll guide you through the steps to pinpoint and fix an EVAP leak. It’s a process that can save you a trip to the mechanic and keep your car running smoothly while protecting the environment. Let’s dive into how to sniff out those elusive leaks and tackle gas fume troubles head-on.

Symptoms of an EVAP Leak

When I suspect my car might have an EVAP leak, I look out for certain signs that indicate the presence of this issue. Knowing these symptoms is the key to diagnosing the problem quickly and effectively.

Firstly, a persistent smell of gasoline around my car is one of the most common indicators. If I’m detecting a fuel odor when the car’s not running or when I’m outside the vehicle, it could signal that gas vapors are escaping from the EVAP system. It’s not just unpleasant; it’s a red flag that something isn’t sealing properly.

Secondly, my car’s check engine light might come on. Modern vehicles are equipped with sensors that can detect even small leaks in the EVAP system. If the system’s integrity is compromised, the car’s onboard diagnostics (OBD) will likely trigger an alert on the dashboard.

Furthermore, I might notice issues with the fuel tank. If it feels like the tank won’t take in gas as smoothly during fill-ups or if the pump keeps shutting off prematurely, it could be due to a problem with the EVAP system not venting correctly. This makes refueling harder than it should be.

Another potential symptom I keep an eye out for is a drop in fuel efficiency. Leaks in the EVAP system can affect the car’s ability to manage fuel vapor, which in turn can impact overall mileage. If I see a sudden change in how often I need to fill up, it‚Äôs worth looking into.

Understanding common symptoms helps in early detection, which in turn aids in maintaining my car’s performance and longevity. It also ensures I’m doing my part to protect the environment by preventing excess hydrocarbons from escaping into the atmosphere. Having these signs in mind, I can proceed to the next step – pinpointing the exact location of the leak.

Understanding the Evaporative Emission System

When I first noticed the signs of an EVAP leak in my car, I knew I needed to understand how the system works. The core function of the Evaporative Emission System is to contain and prevent gasoline vapors from being released into the atmosphere. As a car owner, it’s vital to grasp the basics of this system to troubleshoot effectively.

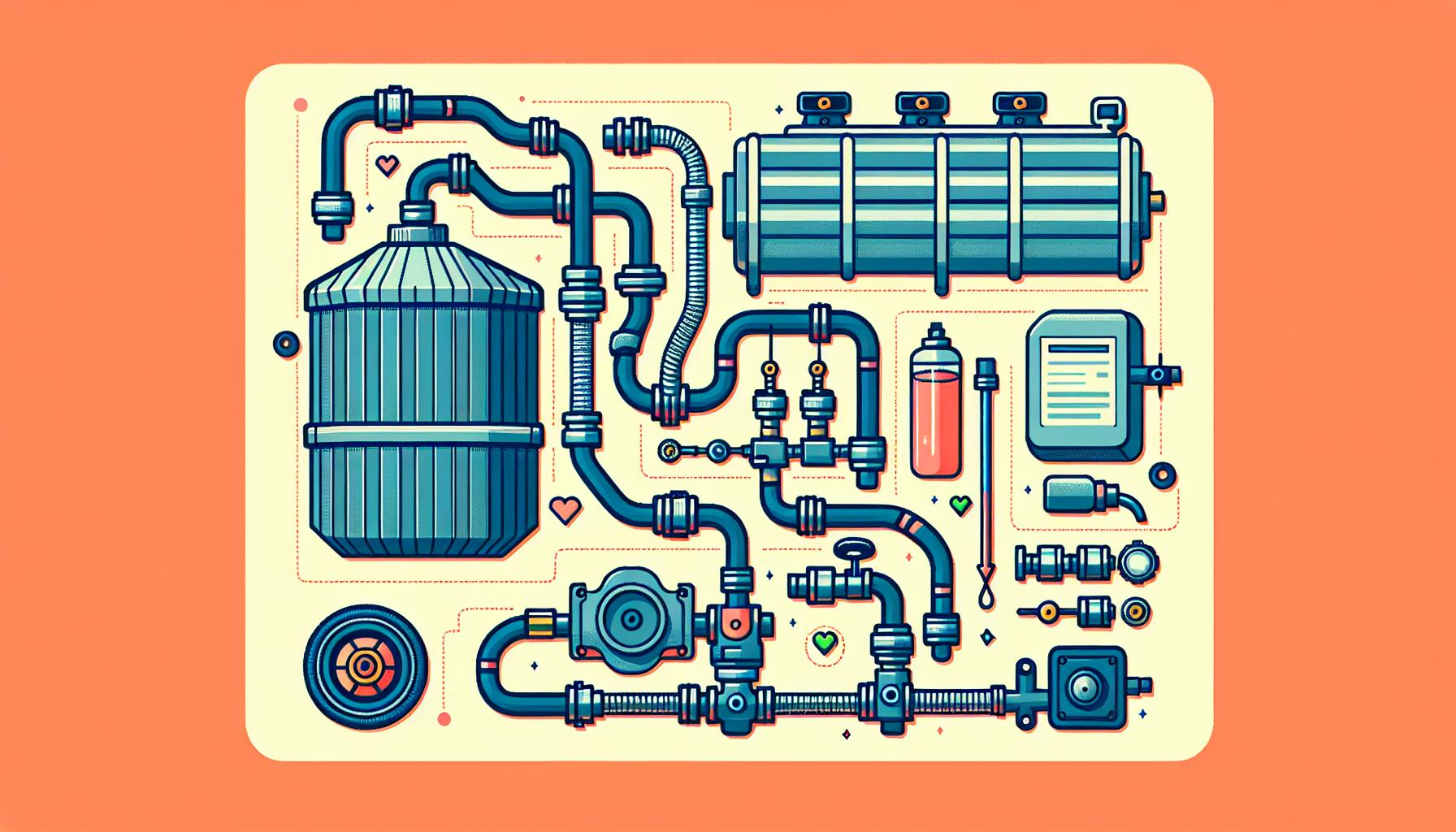

The EVAP system is a network of hoses, vents, valves, and a canister filled with activated charcoal. Its primary role is capturing fuel vapors from the gas tank and storing them in the charcoal canister. When I start my engine, the stored vapors are purged and burned off in the combustion process.

One reason the EVAP system captivates my attention is its impact on the car’s performance and the environment. A well-sealed system ensures that fuel vapors are not wasted into the air, contributing to lower emissions and a more efficient fuel system.

Upon closer inspection, I realized the system is also equipped with pressure sensors that communicate with the vehicle’s onboard computer. These sensors detect any discrepancies in pressure that could indicate a leak. It’s these signals that may trigger the check engine light and alert me to potential issues.

If there’s a leak, it could stem from a variety of causes – loose, worn, or cracked hoses, a faulty gas cap, or a malfunctioning vent valve. Getting familiar with these components allows me to focus my search and find the leak quicker.

Armed with this knowledge, diving into the intricacies of finding the exact location of an EVAP leak seems less daunting. Each component in the EVAP system serves a precise role, and understanding their functions helps me pinpoint where things might have gone astray. Ready to tackle the challenge, I prepare to scrutinize my vehicle, keeping in mind the importance of each part I inspect.

Preparing to Diagnose an EVAP Leak

Before diving into the nitty-gritty of tracking down an EVAP leak, it’s crucial to get everything prepped. A systematic approach will not only streamline the process but also increase the likelihood of pinpointing the problem accurately. First up is gathering the right tools. You’ll need a digital multimeter, a smoke machine designed for EVAP testing, and a hand-held vacuum pump. With these in hand, I’m ready to tackle even the most elusive leaks.

Beyond tools, familiarizing myself with my vehicle’s specific EVAP system layout is essential. Manuals and online forums specific to my car’s make and model are invaluable resources for this. They provide detailed diagrams and troubleshooting tips that are tailor-made for my situation.

Understanding the unique codes that my car‚ computer system reads is another vital step in preparing for diagnosis. When I plug in an OBD-II scanner a device I consider indispensable in modern auto repair‚ it retrieves codes that can indicate a leak’s presence. For instance, a P0442 code would typically signify a small leak, while a P0455 indicates a more substantial breach in the system.

Wearing safety gear is a no-brainer for me. Gloves and protective glasses are my go-to as I handle potentially harmful fumes and chemicals. Also, conducting the diagnosis in a well-ventilated area is crucial since fuel vapors can accumulate quickly.

Once my workspace is safe and everything is in place, I methodically check for obvious signs of wear or damage on the hoses and seals. Sometimes, the culprit is just a loose gas cap or a cracked hose, visible to the naked eye.

By following these preparatory steps, I equip myself for success. Now I’m ready to move on to the actual diagnostic procedures with confidence, knowing I’ve laid the groundwork for an accurate and safe EVAP system inspection.

Using a Smoke Machine to Detect Leaks

When I’m faced with a tough-to-find EVAP leak, my go-to tool is a smoke machine. This device is specifically designed to diagnose leaks by pumping smoke into the EVAP system. Smoke machines are relatively straightforward to use, and they can be a fast way to pinpoint the exact location of a leak.

Firstly, I’ll connect the smoke machine to the service port of the EVAP system. Once the connection is secure, I turn on the machine to begin filling the system with smoke. It’s crucial to ensure there’s enough smoke flowing through. An ample amount helps the escaping smoke become noticeable at the site of any leak, whether it’s a loose hose, a cracked seal, or any other failure point.

I also keep in mind to inspect areas that are prone to leaks. Some common sites include:

- The gas cap

- The charcoal canister

- EVAP hoses and connections

- The purge valve

- The vent valve

Usually, within minutes of running the smoke machine, I can spot a wisp of smoke wafting from the problem area. It’s important to watch closely because some leaks are so small that they’re easy to miss. I often use a bright light to help identify the smoke against the backdrop of the engine bay or undercarriage components.

Using a smoke detector is another tip I recommend. This device can detect the presence of the smoke I’ve introduced into the system, sounding an alarm when it senses the smoke near a leak. This two-fold approach, using sight and sound, enhances my ability to detect even the most minuscule breaches in the EVAP system.

By methodically checking each component and connection, and employing these techniques, I’m able to diagnose and address EVAP system leaks effectively. Remember, a careful and detailed approach is key to successful leak detection, which should not be hurried to avoid overlooking smaller but significant problems within the system.

Other Methods for Finding EVAP Leaks

After discussing the smoke machine technique, I’d like to guide you through other methods to detect leaks in your EVAP system. Keep in mind that smoke machines are effective, but not the only way to troubleshoot.

One alternative is using a handheld vacuum pump. By attaching this tool to various components such as the purge valve, you can apply a vacuum and observe if it holds. If the pressure drops, there’s a good chance you’ve found a leak. This process, although manual, is highly effective for larger breaches in the system.

Another useful tool is an electronic leak detector, also known as a “sniffer.” Designed to pinpoint the exact location of a leak, sniffers detect the hydrocarbons in fuel vapors. When moving the probe around potential leak sites, an increase in the audible tick rate or a change on the digital display will alert you to the presence of a leak.

Don’t overlook a simple visual inspection as well. Sometimes the issue could be as apparent as a disconnected hose or a worn out seal. Here’s what to check for:

- Cracks and wear in hoses and lines

- Tightness of connections and clamps

- Integrity of the gas cap and filler neck

- Condition of the charcoal canister

Maintaining an intact EVAP system not only prevents those pesky check engine lights but also ensures your vehicle runs efficiently. Keeping emissions low is not only beneficial for your car’s performance but also critical for the environment.

Troubleshooting an EVAP leak might initially seem daunting, but with a systematic approach, you’ll often find the culprit in no time. Using these methods, especially in combination, increases your chances of a successful diagnosis. Remember, patience and attention to detail are your best tools in this task.

Fixing an EVAP Leak

When I realize my car’s EVAP system has a leak, it’s crucial to address it promptly to prevent performance issues and maintain compliance with emission regulations. The initial step I take is to verify the source of the leak using the detection methods I’ve mentioned previously, such as smoke machines or special gauges.

Once the leak’s location is pinpointed, I assess whether it’s a simple issue like a loose gas cap or a more complex one such as a cracked hose or faulty valve. For a loose gas cap, tightening or replacing it is often a quick fix. Should I find a defective component, I prepare for a more involved repair process.

Here’s what I typically do if replacement parts are needed:

- Order the correct replacement parts based on my car’s make and model

- Gather necessary tools such as a socket set, screwdrivers, and pliers

- Disconnect the battery before starting any work to ensure safety

- Remove the faulty component carefully to avoid damage to surrounding parts

- Install the new part, double-checking the fit and connections

- Reconnect the battery and run the vehicle to ensure the issue is resolved

I also keep in mind that some components might require special handling or tools, and in such cases, seeking professional help from a certified mechanic could be the best course of action.

It’s imperative to clear any trouble codes from the vehicle‚Äôs onboard computer system after the repair. To do this, I use an OBD-II scanner or sometimes just by disconnecting the car’s battery for a period ‚Äî though I recommend the former for its accuracy and reliability.

Taking proactive steps and performing regular maintenance checks on the EVAP system ensures it continues to operate efficiently. Not only does this help to avoid costly repairs down the road, but it also contributes to a cleaner environment by keeping harmful fumes out of the atmosphere. Regular check-ups include inspecting for cracked hoses and ensuring the gas cap is always securely fastened, which could prevent future leaks and performance issues.

Remember, an effectively functioning EVAP system is integral to a car’s overall health and the well-being of our environment, so keeping it in top condition should always be a priority.